Can AI help to improve the efficiency and accuracy of manufacturing processes?

Are you looking to revolutionize your manufacturing processes and stay ahead in the competitive market? Today, we will explore the potential of Artificial Intelligence (AI) in transforming the way we approach manufacturing. With AI, you can harness the power of advanced data analytics and predictive modeling to optimize production, reduce defects, and increase efficiency. By implementing AI technologies in your manufacturing operations, you have the opportunity to maximize productivity and minimize costly errors. Let’s dive into the world of AI and uncover the game-changing benefits it offers for your manufacturing processes.

Key Takeaways:

- AI can optimize manufacturing processes: By using algorithms and machine learning, AI can analyze large amounts of data to identify patterns and trends, leading to more efficient and accurate manufacturing processes.

- AI can reduce human error: With the ability to automate certain tasks, AI can minimize the risk of human error in manufacturing, leading to improved quality and consistency in the production process.

- AI can enable predictive maintenance: By using sensors and data analysis, AI can predict when machines are likely to fail, allowing for proactive maintenance, reducing downtime, and increasing overall efficiency in manufacturing operations.

AI in Manufacturing: An Overview

If you have been wondering about the role of artificial intelligence (AI) in manufacturing, you are not alone. AI has emerged as a disruptive technology that is transforming the way manufacturing processes are carried out. In this section, we will provide an overview of AI in the manufacturing industry, including its definition and the types of AI technologies that are being applied.

Defining AI in the Context of Manufacturing

When it comes to manufacturing, AI can be defined as the simulation of human intelligence processes by machines, especially computer systems. In this context, AI enables machines to perform tasks that typically require human intelligence, such as visual perception, speech recognition, decision-making, and language translation, among others. In the manufacturing sector, AI is used to improve operational efficiency, product quality, and overall productivity.

Types of AI Technologies Applied in Manufacturing

There are several types of AI technologies that are being applied in the manufacturing industry to enhance efficiency and accuracy. These include:

- Machine Learning: This technology allows machines to learn from data and improve their performance over time.

- Computer Vision: It enables machines to interpret and understand the visual world, leading to applications such as quality control and defect detection.

- Natural Language Processing: AI can process and analyze human language, which is useful in tasks such as customer service and data analysis.

- Robotics: AI-driven robots are capable of performing complex tasks with precision and efficiency, contributing to automation in manufacturing.

- Predictive Analytics: This technology uses data, statistical algorithms, and machine learning techniques to identify the likelihood of future outcomes based on historical data.

This wide array of AI technologies is revolutionizing the manufacturing landscape, paving the way for smarter, more efficient production processes.

Improving Efficiency with AI

One of the significant areas where AI can greatly improve the efficiency of manufacturing processes is in production planning and scheduling, predictive maintenance, as well as robotics and automation.

AI in Production Planning and Scheduling

Your manufacturing operation can greatly benefit from AI-powered production planning and scheduling. By analyzing historical data, AI can identify patterns and trends that can help you optimize production schedules, minimize downtime, and reduce lead times. This can result in significant cost savings and improved on-time delivery performance. AI algorithms can also adapt to changes in demand, machine availability, and other variables, allowing you to make real-time adjustments to your production plans.

Predictive Maintenance and AI

Implementing predictive maintenance through AI can help you prevent costly unplanned downtime and extend the lifespan of your equipment. AI algorithms can analyze equipment sensor data to predict when a machine is likely to fail, allowing you to schedule maintenance proactively. This can save you time and money by avoiding unnecessary equipment downtime and reducing the need for costly emergency repairs.

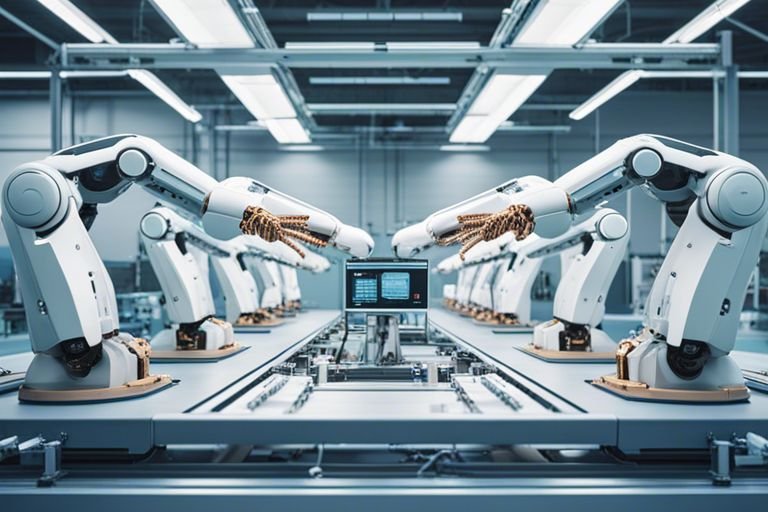

Robotics and Automation

Integrating AI-powered robotics and automation into your manufacturing processes can significantly improve efficiency and accuracy. By automating repetitive and time-consuming tasks, you can free up your workforce to focus on more complex and value-added activities. This can lead to higher productivity, improved product quality, and reduced human error. Additionally, AI can enhance the performance of robots by enabling them to learn from their experiences and adapt to changing conditions in the production environment.

Overall, the integration of AI into manufacturing processes has the potential to revolutionize the industry, bringing about improvements in efficiency, accuracy, and cost-effectiveness. By leveraging the power of AI in production planning and scheduling, predictive maintenance, and robotics and automation, you can stay ahead of the competition and drive your manufacturing operations to new heights of performance.

Enhancing Accuracy with AI

Keep up with the demand for precision and accuracy in your manufacturing processes by integrating AI into your operations. Artificial Intelligence has the capability to enhance the accuracy of manufacturing processes by analyzing vast amounts of data and making real-time adjustments to optimize production outcomes. By leveraging AI, you can significantly reduce human error and improve the overall quality of your products.

Quality Control and Inspection with Machine Learning

Implementing machine learning algorithms for quality control and inspection can revolutionize the way you ensure the integrity of your products. By training AI models to identify defects and inconsistencies in real-time, you can enhance the accuracy of your inspection processes and detect issues that may have been overlooked by human inspectors. This not only improves the overall quality of your products but also reduces the risk of faulty items reaching your customers.

AI in Supply Chain Management and Logistics

Integrating AI into your supply chain management and logistics processes can optimize the efficiency and accuracy of your operations. AI can analyze vast amounts of data to predict demand, optimize inventory levels, and streamline transportation and delivery processes. By leveraging AI in your supply chain, you can minimize the risk of stockouts and overstock situations, ultimately improving the overall efficiency of your manufacturing processes.

Case Studies and Industry Examples

Now, let’s take a look at some case studies and industry examples that demonstrate the impact of AI on manufacturing processes:

- Toyota: Implemented AI in their production process and reduced defective parts by 10%.

- Siemens: Utilized AI for predictive maintenance, resulting in a 20% decrease in downtime.

- Fanuc: Integrated AI for robot control, leading to a 30% increase in production efficiency.

Success Stories of AI Integration

In recent years, many manufacturing companies have successfully integrated AI into their processes, resulting in significant improvements in efficiency and accuracy. Through the use of advanced analytics and machine learning algorithms, these companies have been able to optimize their production lines, reduce downtime, and improve overall quality. By leveraging AI, organizations have been able to gain valuable insights from big data, leading to smarter decision-making and improved performance across their operations.

Challenges and Limitations

While the potential benefits of AI in manufacturing are clear, there are also challenges and limitations that need to be acknowledged. One of the main challenges is the initial investment required to implement AI technologies, as well as the need for skilled personnel to manage and maintain these systems. Additionally, there may be concerns around data security and privacy, as well as potential job displacement as AI takes over certain tasks. It’s important to carefully consider these factors and develop a strategic approach to AI integration in order to maximize its benefits while minimizing potential drawbacks.

The Future of AI in Manufacturing

For manufacturing, the future of AI is full of potential. As technology advances, AI will continue to drive efficiencies, reduce costs, and improve accuracy in manufacturing processes. With the ability to analyze vast amounts of data and make quick decisions, AI has the potential to revolutionize the industry.

Emerging AI Trends in Manufacturing

One of the emerging trends in AI for manufacturing is the use of predictive maintenance. By utilizing AI algorithms, manufacturers can predict when equipment is likely to fail, allowing for proactive maintenance and reducing costly downtime. Additionally, AI-powered robotics and automation are becoming more prevalent, enabling manufacturers to streamline production processes and increase overall efficiency.

The Road Ahead: Predictions and Potential

As AI continues to advance, the potential for its impact on manufacturing is limitless. From optimizing supply chains to improving quality control, AI has the power to transform every aspect of the manufacturing process. However, it’s important to consider the potential ethical and societal implications of AI in manufacturing, such as the displacement of human workers and the need for robust cybersecurity measures to protect AI-powered systems from potential threats.

Can AI Revolutionize Manufacturing Processes?

Upon reflecting on the potential impact of AI in manufacturing, it is clear that AI has the capability to significantly improve the efficiency and accuracy of manufacturing processes. By harnessing the power of machine learning and predictive analytics, AI can optimize production lines, identify defects in real-time, and even predict equipment maintenance needs before they occur. This not only enhances productivity and reduces costs, but also ensures a higher level of quality control. With the integration of AI technologies, your manufacturing processes can be revolutionized to operate at a level of efficiency and accuracy that was previously unattainable. It is evident that AI has the potential to bring about a new era of manufacturing excellence.